Machine to make waffles | Ice cream cones

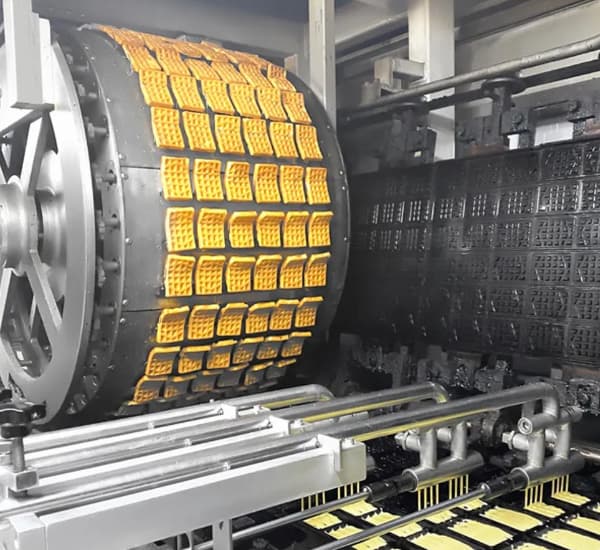

A Machine to make waffles It's a robust team, Generally made of stainless steel, That combines heat, pressure and molds to create perfect waffles in large quantities. These machines are designed for industrial bakeries, ice cream factories, Catering companies and snack producers.

Main functions:

Cooking dough in hot plates

Automatic or semi -automatic rolled

Continuous production without interruptions

Precise temperature and time regulation

Automatic line for wrapped boats

Industrial Electric Machine for Cucuruchos

Continuous machine for boat manufacturing

Machine to make Marquesitas

What is a machine to make waffles?

A professional machine to make boats is a robust team, Generally made of stainless steel, That combines heat, pressure and molds to create perfect waffles in large quantities. These machines are designed for industrial bakeries, ice cream factories, Catering companies and snack producers.

Main functions:

Cooking dough in hot plates

Automatic or semi -automatic rolled

Continuous production without interruptions

Precise temperature and time regulation

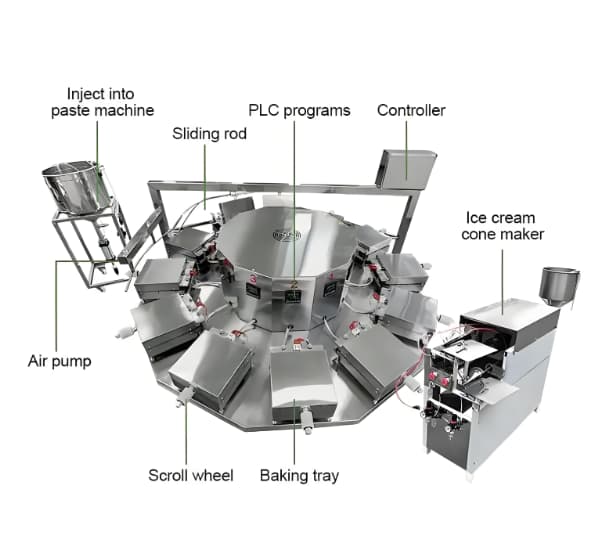

Technical components of a professional boat machine

Las Professional boat machines They are designed with advanced technology. Some common components:

Digital control panel or PLC

Mass automatic feed system

Antiadherent heating plates

Interchangeable molds (Pussy, rollo, plano)

Cooling conveyor belt

Industrial uses and commercial applications Machine for boats

These machines not only produce ice cream cones. They also serve to create products such as:

Filled snack boats

Crispy bases for desserts

Coated barquillo cookies

Crispy yogurt toppings

Industrial cones for ice cream shops

Technical file: Industrial machine

Depending on the model and needs of the client, Technical specifications may vary. Next, We present a table with some typical production capabilities:

| Technical parameter | Standard specification |

|---|---|

| Machine type | Automatic machine for barchillos / Rotary machine for ice cream cones |

| Production capacity | 3,000 – 30,000 Units per hour |

| Product format | Flat ship, Ice Cooler, Rolled ship, WAFER type cookie |

| Type of operation | Automatic or semi -automatic |

| Body material | Stainless steel Food grade (SS 304 / SS 316) |

| Voltage required | 380V / 50Hz (industrial three -phase) |

| Installed power | 12 – 45 KW according to model |

| Energy consumption | Approximately 10 – 40 kWh |

| Heat source | Electric / Gas natural / Propane gas |

| Control system | PLC with HMI touch screen |

| Cooking time | 60 – 120 second adjustable |

| Working temperature | 160°C – 250°C regulable |

| Interchangeable molds | Yeah (cones of different sizes, flat plates, rolled molds) |

| Mass feed system | Automatic with mixing tank |

| Rolled system | Mechanical rolled / air -gifted / Rolled with rotary rod |

| Cooling system | Transporter Band with forced ventilation |

| Team dimensions | 2.5 m – 8 m long (According to configuration) |

| Team weight | 800 kg – 3,000 kg |

| Noise level | <75 dB |

| Certifications | CE, ISO 9001, HACCP |

| Installation requirements | Flat floor, Three -phase electrical connection, adequate ventilation |

| Additional options | Filling dosing, Stacking system, Automatic packaging |

All our machines comply with international quality and safety regulations, guaranteeing efficient and safe functioning.

Rfq- Machine to make waffles,Ice cream cones

1. What is the machine's production capacity?

👉 Answer:

The capacity depends on the selected model. We offer production machines from 3,000 until 20,000 waffles per hour, Ideal for medium and large -scale factories.

2. What type of energy does the machine use? Is it electric or gas?

👉 Answer:

We have models with Electrical warming, a gas natural o GLP, According to customer preference and factory conditions. All models comply with energy efficiency standards.

3. What kind of molds are available? Can they be customized?

👉 Answer:

Yeah, We offer interchangeable molds for different forms: Pussy, profit, flor, fan, Flat cookie, etc. We also manufacture custom molds according to client's samples or plans.

4. What is the manufacturing material of the parties in contact with food?

👉 Answer:

All parties in direct contact with food are made of Food grade stainless steel (THEIR 304 o 316), complying with international health standards (HACCP, CE).

5. Does the machine include automatic control system? Is it easy to operate?

👉 Answer:

Yeah, The machine is equipped with PLC and HMI touch screen. The operator can adjust the temperature, Cooking time and speed easily, With interface in Spanish or English.

6. What type of maintenance does the machine require and how often?

👉 Answer:

The machine requires preventive maintenance monthly: Mold cleaning, Review of engines and axles lubrication. We provide a detailed manual and free remote technical advice.

7. What is the delivery time after the order?

👉 Answer:

The standard manufacturing time is 25 a 35 working days. International shipping depends on destination. We can organize maritime freight, Earth The Air.

8. Do they offer installation and training on the site?

👉 Answer:

Yeah. We offer Installation and Technical Training Service On the site for international clients, or via video called if they prefer. We also deliver videos and manual in Spanish.

9. What guarantees does the machine have and what spare parts are included?

👉 Answer:

We offer guarantee of 12 months For the entire machine, With key pieces included (engines, resistors, PLC, sensors). We send a Free spare kit With each machine.

10. What certifications does the export machine (Europa / Latin America)?

👉 Answer:

The machine has certification CE (European Union), complies with standards ISO 9001 and may include Health documentation (FDA/HACCP) For import processes in Latin America countries.

Machine manufacturers to make boats

In DT Food Machine, We are specialists in the manufacture of industrial machines to make boats, offering high quality solutions for cones producers, boat tubes and cookies worldwide. Our technology is focused exclusively on commercial and industrial use, with production capacity from 3,000 until 20,000 Units per hour.

Why choose us?

Because we combine technological innovation, hygienic design and professional support in each team we manufacture. We use stainless steel materials Certified under certified under regulations CE and ISO, ensuring durability, Safety and ease of cleanliness. Our machines incorporate PLC control with touch screen, customizable molds and gas or electric heating systems.

Besides, We provide international post -sales service, available spare parts, Technical Installation and Complete Training for your Production Team.

DT Food Machine not only sells machinery, Deliver profitable solutions for your business. If you seek efficiency, precision and reliability, We are your best ally.

Machine price to make boats

He Price of a machine to make industrial waffles You can vary considerably according to your production capacity, Automation level, Mold energy and customization source. In DT Food Machine, We offer professional teams exclusively for ice cream factories, replacing the snacks, Not for domestic use.

📊 Estimated price range:

🔹 Semi-automatic models (3,000–5,000 pieces/hour): from USD $2,000 – $15,000

🔹 Automatic models (10,000–20,000 pieces/hour): from USD $5,000 – $45,000+

The price can also include custom molds, Power system, Automatic stack, and conveyor belt for cooled. All our teams are manufactured in stainless steel 304, They comply with CE/ISO regulations, and offer PLC control with HMI touch screen.

For an exact contribution, Contact us with the details of your project:

🔸 Walking type (Pussy, profit, Flat cookie)

🔸 Desired production per hour

🔸 Available energy source (Electric Gas)